Last Updated on July 4, 2023 by PALFINGER

We at PALFINGER MARINE know very well that complex, innovative technology is best explained – and easier to understand – with a visual aid. This time, we would like to introduce you to the development of fully electric jib cranes for low-manned or unmanned offshore operations in collaboration with our long-standing customer and partners Aker BP. Let’s take a look!

One of our more recent stories recounted how Cyrielle Gorini-Gonçalves, one of PALFINGER MARINE’s most talented application engineers, presented the status quo of our almost 10-year development journey to fully electric jib cranes designed for future remote operations at the International Offshore Crane and Lifting Conference in Stavanger, Norway. Reaching TRL 4 in the technology qualification phase represents a major milestone, which is why the presentation gained a great deal of attention – and raised plenty of technical questions. Accordingly, our latest animation explains why this development project is so exciting for the entire industry.

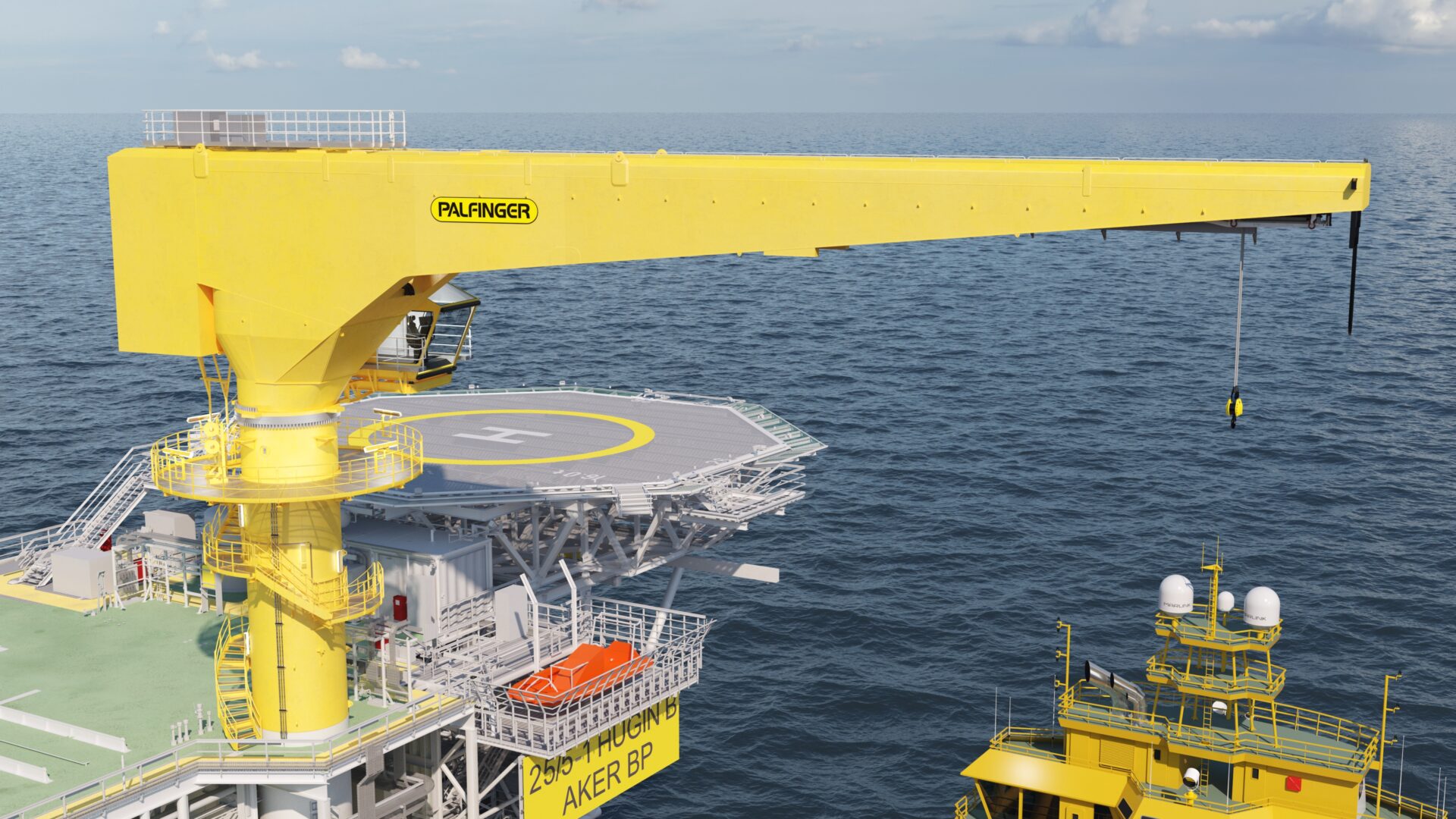

PALFINGER MARINE's fully electric jib cranes are designed for future remote operation.

PALFINGER MARINE x Aker BP: a little background

The underlying case study is an Aker BP order of a total of 7 fully electric cranes – 3 jib cranes, 2 travelling jib cranes, and 2 wire luffing lattice boom cranes – for its Yggdrasil and Valhall oil fields. PALFINGER MARINE is developing these cranes in close cooperation with the customer to meet their specific needs for their unmanned/low-manned offshore operations. The Yggdrasil field, which is featured in the video, entails the Hugin A, Hugin B, and the Munin platforms located between Alvheim and Oseberg in the North Sea. AkerBP is planning extensive infrastructure investment in the area, and the company has once again turned to us as a long-term trusted partner. The following video provides a concise summary of the ongoing project.

PALFINGER MARINE shapes the future of remote lifiting operations

We all know that the weather offshore can be incredibly harsh and unforgiving. This is where our fully electric jib cranes show their full potential. The lifting systems – typically featuring an outreach between 30 and 40 meters and a lifting capacity between 30 and 70 tons – have no exposed components when in parked position, meaning they are well protected against whatever the weather may have in store. It goes without saying that full remote control from an onshore location limits the exposure of personnel to the often harsh conditions offshore.

We cannot stress enough how seriously our customers and us take offshore workers’ safety.

Jan Silgjerd, Head of Global Marine Application Engineering at PALFINGER

Our fully electric jib cranes are also very efficient, using a mere 30 to 50 percent of the energy a conventional offshore crane would consume. The battery room always stores sufficient energy to ensure that the crane is capable of returning to its safe parking position in the event of a power loss. In a time when emissions management is gaining importance, the reduced CO2 discharge of the lifting system is more than an added bonus. PALFINGER MARINE remains fully committed to supporting the ongoing decarbonization of the maritime industry in close collaboration with partners and customers.

PALFINGER MARINE’s roadmap to remote success

So, where does this exciting project stand at the moment? We are proud to report that the engineering phase is progressing at full speed and has reached approximately 33 percent completion. In terms of schedule, the delivery of the pedestals for the fully electric jib cranes is expected to commence early next year. The actual cranes, the beating hearts of the entire lifting systems, will be delivered between late 2024 and autumn 2025. There is still plenty of work to do, but we always welcome a challenge that proves we can #reachanything together.

For more information, check out our previous blog about the fully electric jib crane presentation delivered by our esteemed colleague Cyrielle Gorini-Gonçalves at this year’s International Offshore Crane and Lifting Conference. And don’t forget to keep an eye out for future updates on this exciting, ongoing project. There’s a story to tell here – and we can’t wait to share it with you!

2 comments on “Fully Electric Jib Cranes: Poetry in Motion”