Last Updated on December 15, 2022 by PALFINGER

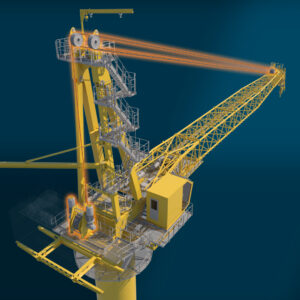

Customization has become a trend in many industries. What has long been standard in the automotive industry, for example, has since seeped into multiple different areas. Every customer is different, every customer has different needs. Given that the same applies to customers operating within the maritime and offshore industry, PALFINGER MARINE has developed a modularized wire luffing lattice boom crane that allows the individual configuration of one of the most indispensable offshore lifting solutions.

Cranes and lifting solutions are used in a myriad of contexts – and every setting is different. PALFINGER MARINE, in its capacity as an industry pioneer, is naturally always interested in meeting its customers’ needs as precisely as possible. The next logical step in the development of customer-centric solutions for the offshore and oil and gas industries is customization. What has long been standard in many consumer industries, has now arrived in the industrial sphere – and PALFINGER is at the forefront of the revolution. Let’s take a closer look at the development and capabilities of our modularized wire luffing lattice boom crane. This is the story of how customers not merely come first, but how they themselves can become developers of sorts.

Yet what exactly does customization mean in terms of crane and lifting solutions? PALFINGER MARINE has always been committed to customer centricity, so this new solution allows customers to configure a crane that suits their specific needs perfectly, from cabin to luffing winch. It’s like reading a menu in a restaurant of lifetime excellence. In terms of our modularized wire luffing lattice boom crane, this involves, for example, a choice of electro-hydraulic, diesel-hydraulic, or fully electric power systems. The main and auxiliary winch systems come in lattice boom lengths between 36 and 60 meters. Maintenance access comes in stairs or ladders. It goes without saying that the modularized crane features a redundant luffing system that increases safety and prevents boom or load drops. Furthermore, the crane can be prepared for future remote operation.

- The main and auxiliary winch systems come in different in lattice boom lengths …

- … ranging between 36 and 60 meters

- Upon the customers’ request, the modularized crane is delivered with a standard luffing system, or …

- … a redundant luffing system that increases safety and prevents boom or load drops.

Product Development as a Team Process

But let’s find out more about the development process from someone who was directly involved. Rene Jenensch, PALFINGER MARINE Global Product Manager, looks back: “The development process of the modularized wire luffing lattice boom crane itself took less than two years from when then project started in May 2020 to the official product release in January 2022. The actual engineering phase began in December 2020.” All the hard work in the name of customer centricity has paid off, solving a string of challenges along the way.

Alongside the advantage of being able to adapt to customer needs quickly, the scalable, modularized solution boasts many other benefits. A repeatable manufacturing and assembly platform results in a high-quality product with short delivery times due to optimized processes and engineering. Furthermore, maintenance of a modularized system is significantly more efficient. “Seeing that the product was developed under clear, consistent, and transparent guidelines, it is also fully aligned with all departments along the value chain,” Rene adds.

“PALFINGER is a team, so having all divisions, from sales to production, on board is a huge asset.”

Rene Jenensch, PALFINGER MARINE Global Product Manager at PALFINGER MARINE

Pioneering Industry Trends

PALFINGER MARINE always strives to be at the forefront of industry trends – and the modularized wire luffing crane is no different. “Autonomy is a major driver in our industry. If you consider the crane itself as the skeletal body with muscles, its sensors are its eyes and ears. And the control system is the brain,” Rene explains. Another major trend is sustainability. “This system addresses a string of related issues. It makes operations greener through electrification, for example. High material utilization also feeds into the sustainability topic.”

So, how has the modularized wire luffing crane been received by the market? We caught up with Cyrielle Gorini-Gonçalves, PALFINGER MARINE Sales Engineer, to find out more. Unsurprisingly, she has exciting news to share: “The two ongoing projects involve four fully electrical modularized cranes for a FPSO and an offshore platform where two of them will be prepared for future remote operations.” And what about the future? “Given that this crane system adapts so excellently to customer needs and has a strong focus on remote operations, it is no surprise that there are several future projects on the horizon.”

Given the challenges our industry faces, PALFINGER MARINE remains fully committed to pioneering and advocating change for the better. Our crane and lifting solutions embrace new trends while respecting their heritage. The development of the modularized wire luffing lattice boom crane is merely the first step on the path to a whole new level of customer focus. The future is brighter than ever.