Last Updated on August 14, 2024 by PALFINGER

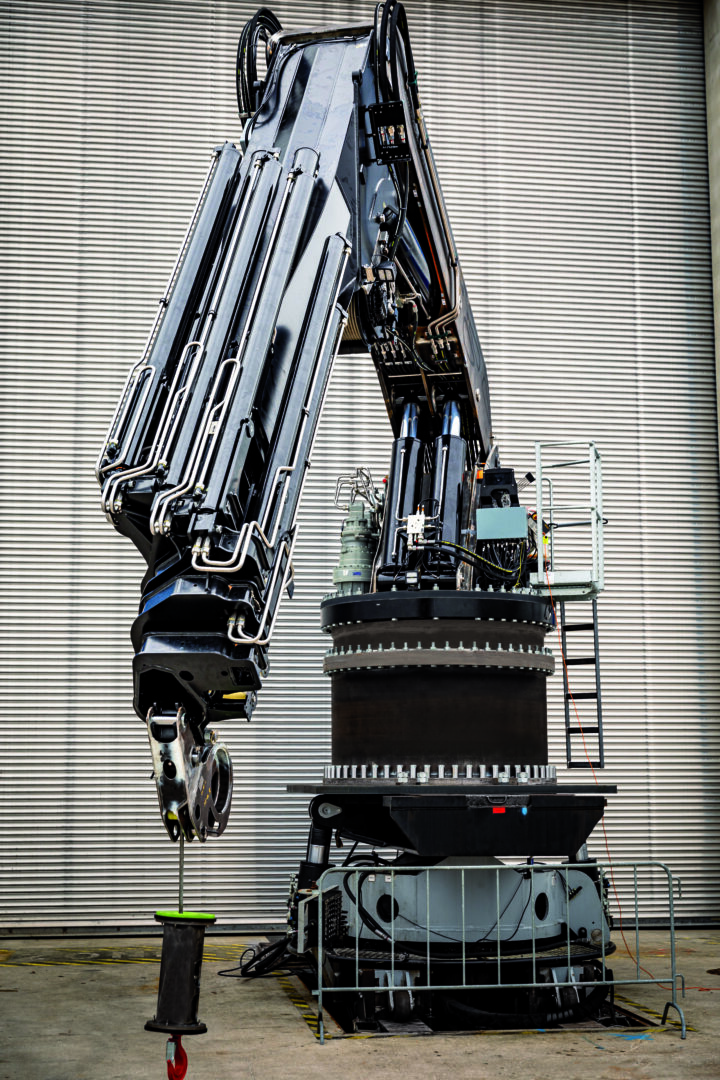

PALFINGER MARINE is gearing up to launch its new PFM 2100 crane series to the industry at the SMM trade show in Hamburg. The all-new model features a 29-meter maximum outreach at a comparatively high load capacity, giving the crane a significant edge over its direct competition. This second blog article of four sheds a light on the comprehensive testing process.

TESTING THE LIMITS OF WHAT’S POSSIBLE

In our last blog, we found out how our experts designed and built the prototype of our new PFM 2100 crane. The next phase involved subjecting the new model to a rigorous testing procedure. To this end, the crane was moved from the prototype assembly area to a dedicated outdoor testing area in Köstendorf, Austria, for an initial functional test conducted by Martin Faistauer, Prototype Testing Technician. At the heart of our commitment to excellence lies the assurance that our products not only meet but exceed industry standards. This dedication drove us to subject our prototype to a series of tests, ensuring that it can withstand the demands of real-world application.

Following regular load tests to verify the crane’s lifting capacity and stability, the new model was forced to exceed its limits at 125% capacity and mastered the challenge with flying colors. Additional speed tests evaluated the PFM 2100’s agility in maneuvering loads with precision at speed, to ensure it holds up in today’s fast-paced industrial landscape where every second counts. Last but certainly not least, safety tests formed an integral part of the functional testing process: from emergency stop mechanisms to fail-safe protocols, every aspect of the crane’s features was put to the test.

In the course of the functional testing, which lasted approximately one month, our crane moved no less than 400 tons.

Martin Faistauer, Prototype Testing Technician

PALFINGER MARINE IS WILLING TO GO THE FULL DISTANCE

In our pursuit of new standards in terms of reliability and safety, the PFM 2100 was then subjected to a lifetime endurance test that started May 2024. This 24/7 test, based on pre-defined parameters, was conducted in a fully automated manner. Each test cycle involved an active movement, which was then followed by a dedicated phase of meticulous monitoring and analysis. The entire process was filmed for documentation.

The PFM prototype at our outdoor testing area in Austria.

The aim of the endurance test was to validate the fatigue calculations of the crane structure. Integral to the endurance test were the strain gauges, which monitored the structural integrity of critical components like the main boom. Our engineers analyzed strain gauge data to evaluate crane performance under various loads. Additionally, strain gauge measurements verified our design calculations and provided real-time feedback during tests, allowing adjustments to ensure safety and reliability.

It’s fair to say that PALFINGER MARINE left no stone unturned during the testing procedure of our new PFM 2100 model. Just to give you an idea of the extent of this endurance evaluation:

The crane lifted a staggering 100,000 tons and performed 3,125 full rotations in the course of the endurance test.

We are more than happy to announce that the crane has successfully completed the endurance test, thus demonstrating its robustness and resilience.

THE PFM 2100 ATTRACTS ATTENTION

It is no surprise that our new PFM2100 has been turning heads ever since its upcoming launch was announced. Our long-term partner Bergen Hydraulic, who have already sold two of the new crane models, popped by to have a closer look at the prototype. A little later, we welcomed representatives of DNV and Lloyd’s Register, the world’s leading classification societies, in Austria for a tour of our production and testing facilities. Needless to say, everyone left impressed with what they saw.

WHAT’S NEXT?

As we look towards the future, we’re excited to announce that we are kicking off serial production at our state-of-the-art facility in Marburg, with the first two PFM cranes scheduled to head to Norway by early 2025. Stay tuned for more updates!