Last Updated on March 31, 2022 by PALFINGER

Inspiration can strike anywhere. Nowhere more so, some would say, than at a trade show during an in-depth conversation with dedicated peers. At an exhibition in London, Torstein V. Svane, Senior Sales Manager at PALFINGER, found himself discussing uncrewed surface vehicles (USVs) with trade show participants representing Atlas Elektronik UK (AEUK). The conversation turned to the difficulties of launching and recovering AEUK’s highly acclaimed ARCIMS USVs in offshore conditions. This is the story of how two specialists developed a new, innovative solution that will benefit many – a state-of-the-art USV slipway system.

Torstein remembers that day at the DSEI well. “It swiftly became clear that the launch and recovery of ARCIMS USVs is made particularly challenging by the fact that there is no crew on the USV in question to assist in hooking the vessel to a davit or crane. Furthermore, such large boats would require a rather complicated lifting system that needs the attention of multiple deck crew members, as well as operators for the crane/davit and painter boom.” Apart from being time-consuming, the process also increases the risk of accidents.

Perfect Match

Barry Webster, Sales & Product Manager at AEUK, confirms that they had been monitoring the market for new solutions that could simplify and improve launch and recovery operations for quite some time.

When we investigated the slipway system technology developed by PALFINGER, we immediately recognized its huge potential.

Barry Webster, Sales & Product Manager at AEUK

Torstein adds, “We have continously refined our slipway technology. Our solutions allow the launch and recovery of USVs to be carried out remotely without manual crew involvement.” If this isn’t the perfect foundation for an exciting collaboration, what is?

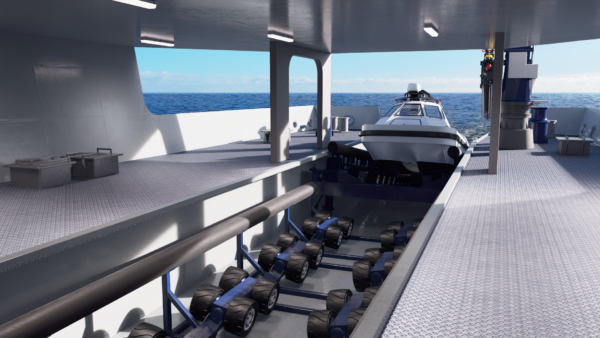

The slipway’s key technology are the powered self-adjusting wheel drive units in two parallel rows along the slipway slope at the stern of the mother vessel.

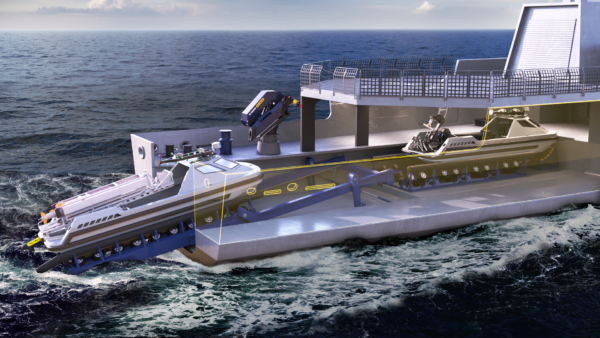

PALFINGER and AEUK subsequently agreed to develop a joint solution based on existing PALFINGER slipway technology, namely the reliable PQBS quad-wheel slipway system that has been on the market for more than ten years. A preliminary feasibility study was launched, followed by a pitch of an underlying concept to AEUK. PALFINGER developed what would later be known as the PQBS-T-D-P system in close collaboration with AEUK. Our order book currently consists of ten slipway systems using a similar drivable cradle as well as two slipway systems with a similar parking position for a second boat.

The new slipway design can handle two USVs on the same mother vessel.

The load capacity of the PQBS-T-D-P model is 12 metric tons and it is specifically designed to handle the twin-hull design of the ARCIMS USV. By adding a powered parking position that automatically transfers the USV to and from the slipway for launch and storage, the system is capable of handling two of the USVs in question on the same mother vessel.

PALFINGER’s slipway systems already feature onboard multiple vessel types around the world. The key technology of the unique slipway system is the use of powered self-adjusting wheel drive units, called quad units, arranged in two parallel rows along the slipway slope at the stern of the mother vessel. Once the boat makes sufficient contact with the quad units, the powered wheels will adapt to the hull shape of the boat and drive it up the slipway slope before docking it safely inside the slipway.

Win-Win Solution

Even though the new PQBS-T-D-P slipway system was designed and configured using high-definition 3D models and simulations based on AEUK’s ARCIMS USVs, the new solution can be adapted to other clients and their vessels. Both Torstein and Barry are thrilled with the result of the collaboration and its successful introduction to the market. They and the development teams at both PALFINGER and AEUK have every reason to be proud of their achievements. Talk about a win-win situation!