Last Updated on November 8, 2024 by PALFINGER

Imagine strapping yourself into a lifeboat with 69 colleagues and free falling into the North Sea from a height of 29 meters. That’s what workers on the Johan Sverdrup oil rig need to train and prepare for in case an emergency strikes. PALFINGER MARINE won the contract to deliver nine FF1200 systems to Johan Sverdrup including one movable top unit, which will be mounted onto the platform’s living quarters.

Just Millimeters of Room for Error

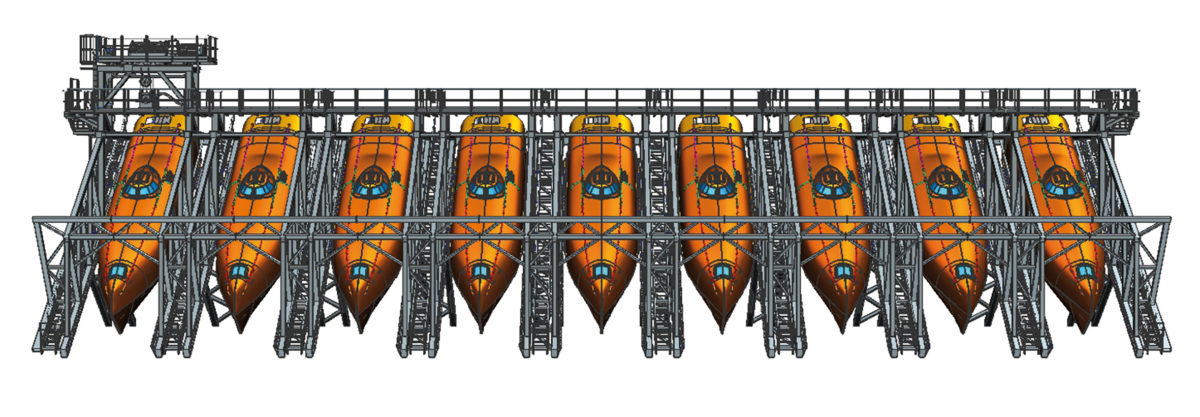

“In the past we had only delivered up to four systems in one structure. The Johan Sverdrup project required nine,” Oddgeir Maelen, Global Sales Manager at PALFINGER MARINE says. “The physical dimensions presented a real challenge, as the structure has a total length of around 55 meters and a tolerance of less than one centimeter. However, we knew we had the skills and experience to manage the job successfully.” The system’s incredible size isn’t the only thing special about the equipment delivered to the Johan Sverdrup site: “The lifeboats are a standard model according to our frame agreement with Statoil, but they are the first to be delivered with Lifeboat Navigation Assistant, including Automatic Escape System.” This special technology includes a servo steering unit and an autopilot that is activated during free-fall and guides the lifeboat away from the platform in an emergency situation.

How to Test a Free-Fall Lifeboat

According to regulations all lifeboats need to be free-fall tested before being taken into service. Needless to say, testing this equipment was an extensive process. “To minimize the amount of offshore testing we drop tested all lifeboats at our location in Seimsfoss, Norway: once from 29 meters and then nine times from 33 meters,” Oddgeir says. Lasting five days, visitors came from K2JV and Statoil – the client and end customer respectively – as well as DNV and Sintef Ocean, who documented g-forces and other important measurements. But they weren’t the only special guests.

TESTING THE LIFEBOATS IS REALLY SPECTACULAR TO SEE, SO WE HAD KIDS FROM SEVERAL OF THE LOCAL SCHOOLS AND KINDERGARTENS COMING TO WATCH TOO.

Oddgeir Maelen, Global Sales Manager

From Project Signing to Delivery

Oddgeir Mælen was responsible for the project from the early stages in 2013 until the contract was signed. The Johan Sverdrup project is a big one: “We had to win this prodigious project in strong competition and a tough market. That’s something we’re really proud of”. Production ran from early 2016 to mid-2017, with the davits delivered in September 2017 and the lifeboats in May 2018. Oddgeir’s and the team’s involvement in the Johan Sverdrup delivery isn’t wrapping up just yet though: “Installation and testing on the platform will continue throughout next summer and we still have weekly meetings with the customer,” he says, “but we are delighted to have finished the equipment on time and to their satisfaction.”

Illustration of the Johan Sverdrup living quarters, © Statoil ASA

Complete Deck Equipment Supplier

For the Johan Sverdrup project, PALFINGER MARINE is not only delivering state-of-the-art lifesaving appliances, but also seven fully electric offshore cranes. Click to find out more about the project and the cranes delivery and installation.